0555-6768298

0555-6768298

0555-6768298

0555-6768298

Jika Anda memiliki pertanyaan atau saran, silakan tinggalkan pesan kepada kami, kami akan membalas Anda sesegera mungkin!

hubungi kami

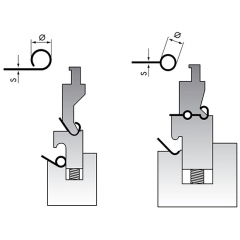

Keuntungan Produksi dalam dua atau tiga langkah Mengurangi tanda melalui perangkat penahan pegas Komponen aktif diperkeras Pengulangan tinggi melalui backgauge terintegrasi Uji fungsional dan penyesuaian melalui tikungan uji - dengan lembar sampel Anda Cocok Untuk Ketebalan material minimal hingga 4,0 mm bagian dalam Ø : 2,5 mm x tebal material untuk baja dan alumunium 3,0 mm x tebal material untuk stainless steel

Tekan rem rolla-v mati tanpa goresan, sebaiknya letakkan film di permukaan benda kerja saat Anda menekuk. dan kami akan merekomendasikan ukuran cetakan roll-v yang sesuai untuk Anda sesuai dengan pelat yang Anda tekuk.

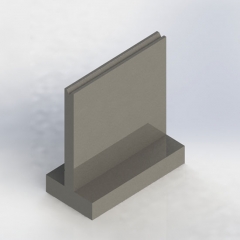

Shim Style Adjustable Dies Dies bawah yang dapat disesuaikan dapat dianggap sebagai salah satu tambahan paling serbaguna untuk rem pers. Dengan jenis alat ini bukaan dapat diatur dari 6.35mm hingga 381mm. Spacer disediakan untuk menghasilkan bukaan yang diperlukan. Slotted spacer memungkinkan pelepasan yang mudah untuk mengubah lubang cetakan. Saat tidak digunakan, spacer diposisikan di sisi blok cetakan. Cetakan ini dapat dilengkapi dengan panjang padat atau dipotong untuk penanganan yang lebih mudah.

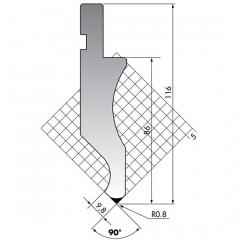

Ukuran pisau lurus: 835 * 146 * 26mm, 90 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

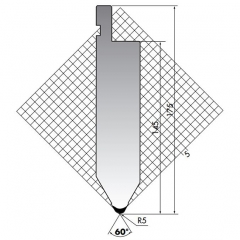

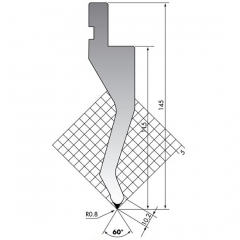

Ukuran pisau lurus: 835 * 175 * 40mm, 60 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

Ukuran pisau lurus: 835 * 146 * 26mm, 90 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

Ukuran pisau lurus: 835 * 145 * 32mm, 60 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

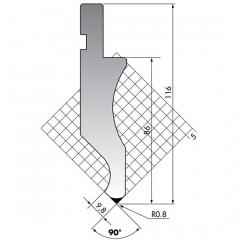

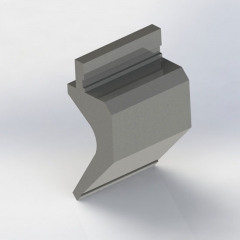

Ukuran pukulan gooseneck: 835 * 197 * 92mm, 88 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3. dan tinggi 197mm, lebar 92mm. dapat dibuat sesuai dengan permintaan pelanggan.

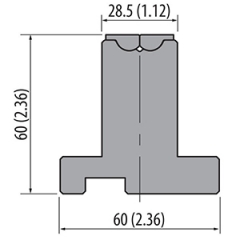

Ukuran mati TV: 835 * 120 * 60mm, V12,30 derajat. bahannya 42CrMo4, kekerasannya HRC52-58. dan V6,V8,V10,V16,V20,V25 dapat dibuat sesuai permintaan pelanggan.

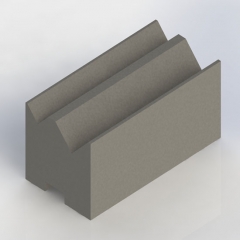

Self centering 2V mati, ukurannya 835 * 46 * 50mm, 88 derajat, beratnya 17kg. Dan kita bisa membuat V5-V9, V8-V12, V12-V20, V16-V25 dan bukaan V lainnya sesuai ketebalan lentur.

Apa material terbaik untuk perkakas mesin press brake?

Di bidang fabrikasi lembaran logam Pemilihan material untuk perkakas mesin press brake secara langsung menentukan ketahanan aus, masa pakai, dan akurasi pembentukannya. Untuk memastikan efisiensi produksi dan kualitas produk, pemilihan material perkakas secara ilmiah sangatlah penting. Namun, dengan begitu banyak pilihan material yang tersedia di pasaran, pelanggan seringkali bingung saat mengambil keputusan. Jadi, bagaimana cara memilih material perkakas yang "terbaik"? Artikel ini akan membahas topik ini dari empat perspektif utama.

Berdasarkan Jenis Material Lembaran

Berbagai jenis material lembaran membutuhkan material perkakas yang berbeda. Yang paling umum digunakan rem tekan Cetakan Material yang tersedia di pasaran meliputi 42CrMo, T8/T10, H13, dan SKD11/D2. Di antaranya, baja paduan berkekuatan tinggi dan tangguh. seperti 42CrMo adalah Cukup memadai untuk sebagian besar tugas pembengkokan umum. Namun, untuk material seperti baja tahan karat, yang memiliki kekuatan dan daya lentur lebih tinggi, material perkakas yang lebih keras dan lebih tahan aus seperti SKD11 atau H13 lebih cocok.

Berdasarkan volume produksi dan frekuensi penggunaan

Untuk lini produksi jangka panjang atau operasi frekuensi tinggi, sebaiknya gunakan material yang lebih tahan aus seperti H13 atau SKD11. Meskipun biaya awalnya lebih tinggi, material ini secara signifikan mengurangi waktu henti dan penggantian peralatan. Untuk produksi dalam jumlah kecil atau penggunaan sesekali, 42CrMo menawarkan keseimbangan yang baik antara kinerja dan keterjangkauan.

Berdasarkan persyaratan presisi

Komponen lembaran logam presisi tinggi seringkali membutuhkan kekerasan dan stabilitas yang lebih tinggi dari perkakas. Dalam kasus seperti itu, disarankan untuk menggunakan material dengan kekerasan tinggi seperti SKD11 untuk mencegah deformasi dan mempertahankan sudut tekukan yang konsisten dari waktu ke waktu. Perkakas dengan kekerasan lebih rendah lebih mungkin aus atau berubah bentuk dengan penggunaan yang lama, yang dapat berdampak negatif pada akurasi produk.

Berdasarkan Biaya

Secara umum, material perkakas berkualitas tinggi cenderung lebih mahal, tetapi menawarkan masa pakai yang lebih lama dan membutuhkan perawatan yang lebih sedikit. Dalam jangka panjang, meskipun investasi awal lebih tinggi, biaya penggunaan secara keseluruhan sebenarnya lebih rendah. Bagi pelanggan yang memprioritaskan efisiensi dan stabilitas, memilih material bermutu tinggi adalah investasi yang bijaksana.

Kesimpulannya, tidak ada jawaban standar tunggal dalam hal pemilihan material perkakas mesin press brake. Pilihan yang tepat harus didasarkan pada evaluasi komprehensif terhadap jenis material, tujuan produksi, persyaratan kualitas, dan anggaran.

Di Golin, kami berkomitmen untuk menggunakan material berkualitas tinggi seperti 42CrMo dan SKD11, dikombinasikan dengan proses perlakuan panas canggih untuk memastikan perkakas kami kuat dan tahan lama. Kami juga menawarkan pilihan material dan kekerasan yang disesuaikan dengan kebutuhan pembengkokan spesifik pelanggan kami. Jika Anda memiliki pertanyaan lebih lanjut atau ingin mempelajari lebih lanjut, jangan ragu untuk menghubungi kami kapan saja!

on line

on line 0555-6768298

0555-6768298 0555-6769126

0555-6769126 sales2@cngolin.cn

sales2@cngolin.cn +86 18251802252

+86 18251802252