0555-6768298

0555-6768298

0555-6768298

0555-6768298

Jika Anda memiliki pertanyaan atau saran, silakan tinggalkan pesan kepada kami, kami akan membalas Anda sesegera mungkin!

hubungi kami

Keuntungan Produksi dalam dua atau tiga langkah Mengurangi tanda melalui perangkat penahan pegas Komponen aktif diperkeras Pengulangan tinggi melalui backgauge terintegrasi Uji fungsional dan penyesuaian melalui tikungan uji - dengan lembar sampel Anda Cocok Untuk Ketebalan material minimal hingga 4,0 mm bagian dalam Ø : 2,5 mm x tebal material untuk baja dan alumunium 3,0 mm x tebal material untuk stainless steel

Tekan rem rolla-v mati tanpa goresan, sebaiknya letakkan film di permukaan benda kerja saat Anda menekuk. dan kami akan merekomendasikan ukuran cetakan roll-v yang sesuai untuk Anda sesuai dengan pelat yang Anda tekuk.

Shim Style Adjustable Dies Dies bawah yang dapat disesuaikan dapat dianggap sebagai salah satu tambahan paling serbaguna untuk rem pers. Dengan jenis alat ini bukaan dapat diatur dari 6.35mm hingga 381mm. Spacer disediakan untuk menghasilkan bukaan yang diperlukan. Slotted spacer memungkinkan pelepasan yang mudah untuk mengubah lubang cetakan. Saat tidak digunakan, spacer diposisikan di sisi blok cetakan. Cetakan ini dapat dilengkapi dengan panjang padat atau dipotong untuk penanganan yang lebih mudah.

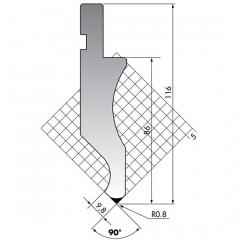

Ukuran pisau lurus: 835 * 146 * 26mm, 90 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

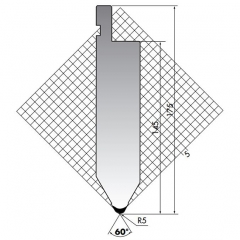

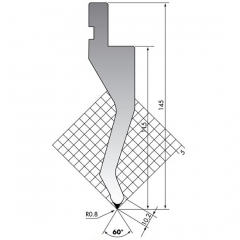

Ukuran pisau lurus: 835 * 175 * 40mm, 60 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

Ukuran pisau lurus: 835 * 146 * 26mm, 90 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

Ukuran pisau lurus: 835 * 145 * 32mm, 60 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3

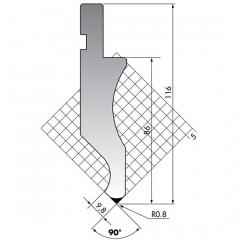

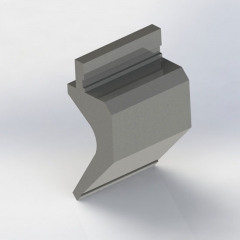

Ukuran pukulan gooseneck: 835 * 197 * 92mm, 88 derajat. bahannya 42CrMo4, kekerasannya HRC47+/-3. dan tinggi 197mm, lebar 92mm. dapat dibuat sesuai dengan permintaan pelanggan.

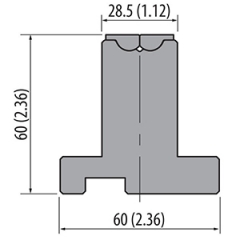

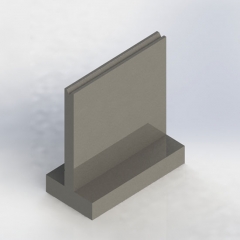

Ukuran mati TV: 835 * 120 * 60mm, V12,30 derajat. bahannya 42CrMo4, kekerasannya HRC52-58. dan V6,V8,V10,V16,V20,V25 dapat dibuat sesuai permintaan pelanggan.

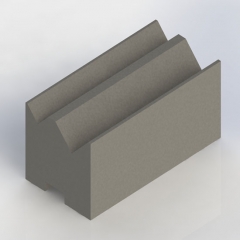

Self centering 2V mati, ukurannya 835 * 46 * 50mm, 88 derajat, beratnya 17kg. Dan kita bisa membuat V5-V9, V8-V12, V12-V20, V16-V25 dan bukaan V lainnya sesuai ketebalan lentur.

Dalam proses pembengkokan tradisional, cetakan sering meninggalkan penyok atau goresan pada permukaan lembaran logam. Masalah ini terutama terlihat saat memproses panel cermin baja tahan karat, lembaran aluminium, atau komponen dekoratif, yang secara signifikan mengurangi penampilan dan nilai keseluruhan produk, dan terkadang bahkan menyebabkan pengerjaan ulang atau pembuangan. Dengan meningkatnya permintaan akan kualitas permukaan dalam manufaktur, alat pembengkokan bebas goresan telah muncul.

Jenis-jenis Alat Press Brake Bebas Goresan :

Alat pembengkokan bebas gores dirancang dengan struktur atau material khusus untuk mencegah goresan dan penyok. Jenis umum meliputi:

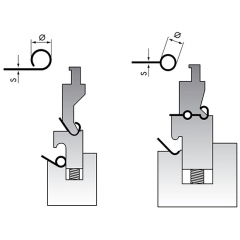

Alat bebas goresan dengan bantalan bola: Alat ini menopang lembaran logam melalui bantalan bola, secara signifikan mengurangi gesekan, secara efektif mencegah goresan, dan membuat proses pembengkokan lebih lancar.

Alat bebas goresan tipe putar: Permukaan penyangga dapat berputar sesuai dengan sudut tekukan, sehingga menghindari kerusakan permukaan. Mekanisme putar yang fleksibel ini memastikan lembaran logam ditopang secara merata selama proses tekukan, mencegah penyok lokal.

Alat dengan bantalan poliuretan anti gores: Menggunakan bantalan fleksibel untuk melindungi lembaran logam, alat-alat ini sangat cocok untuk pemrosesan lembaran logam dengan presisi tinggi dan kualitas permukaan yang tinggi.

Keunggulan Alat Pembengkokan Bebas Goresan:

Dibandingkan dengan alat tradisional, cetakan bebas gores menawarkan keunggulan yang jelas dalam pemrosesan lembaran logam:

Lindungi permukaan lembaran logam: Cegah penyok dan goresan, memastikan tampilan berkualitas tinggi.

Mengurangi biaya material: Meminimalkan pengerjaan ulang dan pemolesan, meningkatkan efisiensi produksi. .

Adaptabilitas tinggi: Cocok untuk berbagai material dan ketebalan, memenuhi beragam persyaratan proses

Memperpanjang masa pakai cetakan: Struktur bantalan bola atau bantalan mengurangi keausan, sehingga memperpanjang masa pakai alat.

Bahan dan Bidang Industri yang Berlaku:

Alat pembengkok bebas goresan banyak digunakan untuk lembaran logam yang membutuhkan kualitas permukaan sangat tinggi, termasuk panel cermin baja tahan karat, lembaran aluminium, lembaran galvanis, dan panel dekoratif yang dilapisi atau dicat. Alat ini diaplikasikan di berbagai industri manufaktur kelas atas, seperti:

Dekorasi lift dan arsitektur: Untuk panel lift, dinding tirai logam, dan berbagai komponen dekoratif baja tahan karat.

Peralatan dapur dan peralatan rumah tangga: Untuk pembuatan wadah peralatan masak, lemari es, mesin cuci, dll., memastikan permukaan yang halus dan menarik.

Peralatan medis dan presisi: Untuk bagian lembaran logam dari perangkat medis, instrumen pengujian, dan aplikasi lain dengan persyaratan integritas permukaan yang ketat.

Pengerjaan logam lembaran khusus kelas atas: Seperti komponen kedirgantaraan atau interior mewah, di mana detail permukaan dan kualitas sangat penting.

Singkatnya, alat pembengkokan tanpa gores tidak hanya meningkatkan kualitas permukaan produk tetapi juga membantu perusahaan pengolahan lembaran logam mengurangi biaya produksi dan meningkatkan efisiensi. Dalam beberapa tahun terakhir, Golin Tooling telah mengikuti perkembangan zaman di bidang pembengkokan tanpa gores, mengembangkan dan meluncurkan berbagai alat pembengkokan tanpa gores, yang telah dijual ke Eropa, Amerika Selatan, dan sebagian Timur Tengah, serta menerima pujian yang konsisten dari pelanggan. Ke depannya, permintaan akan pembengkokan tanpa gores di bidang manufaktur kelas atas akan terus meningkat, dan Golin akan terus menyediakan solusi perkakas yang profesional dan efisien kepada pelanggan di seluruh dunia.

on line

on line 0555-6768298

0555-6768298 0555-6769126

0555-6769126 sales2@cngolin.cn

sales2@cngolin.cn +86 18251802252

+86 18251802252